Threaded Bar

Threaded bars is a hot-rolled solid bar with discontinuous external threads. It can be connected by coupler. When threaded bars are used in the field of anchoring, according to the requirements of the anti-corrosion grade, it can form different anti-corrosion systems with couplers, nuts, plates, corrugated pipes, smooth plastic pipes, end caps, and so on.

- Application: Due to its high strength and flexible construction, threaded bar can be used as reinforcement cages, reinforcement beams, reinforcement meshes, soil nails, rock bolts, formwork tie rods, back pulls, micro piles, ground anchors and other structures. It is widely used in various construction scenarios such as building construction, dam reinforcement, slope support, tunnel support, hanging basket tensioning, and tower foundation. Usually used in conjunction with concrete, it has played a huge role in engineering construction.

- Main diameter: 20 (left), 25 (right), 32 (right). Customized specifications are also available such as 28 (right), 34 (right).

- Material: PSB500, PSB830, PSB930, PSB1080, and PSB1200.

Hot-dip Galvanized Coating Requirements

| Product Specification | Local Coating Thickness (um) | Mean Coating Thickness (um) | Max. Coating Thickness (um) |

|---|---|---|---|

| Refined Rolled Thread Bar | 70~200 | 85 | 200 |

Class I Anti-corrosion System

Class I anti-corrosion anchoring system is suitable for semi-permanent support and permanent support in corrosive environment. Anchorage section is protected by corrugated pipe, end cap, cement grout, and the free section is protected by smooth plastic pipe.

Class II Anti-corrosion System

Class II anti-corrosion anchoring system is used for temporary support in corrosive environment and semi-permanent support in non-corrosive environment. Anchorage section is protected by cement grout, and the free section is protected by smooth plastic pipe.

Non-anticorrosive System

Non-anticorrosive anchorage system is suitable for temporary support in non-corrosive environments, and cement grout will protect the anchoring section.

Grouting method of threaded bar

1. Assemble the threaded bar and internal grouting solidification anti-corrosion system and put it into the hole.

2. Insert the exhaust pipe and the grouting pipe. Grouting pipe should reach the bottom of the hole, grouting method is pulling out the grouting pipe while grouting, and start the grouting pipe should be pulled out after grouting to 5m.

3. Use PO 42.5 ordinary Portland cement to prepare cement slurry, the water-cement ratio is controlled at 0.4-0.45, and the grouting pressure is controlled at 0.4-0.6Mpa until the orifice overflows. At this time, all the exhaust pipes should be pulled out and the grouting pipes should not be pulled out.

4. Use cement bag wet clay plus steel plate to seal and tightly plug, grout at 0.4-0.6Mpa stably for 5min, then pull out the grouting tube.

5. The grouting volume should be greater than 1.2 times its theoretical calculated volume.

6. After grouting, install the plate and nut.

- Threaded rod

- Accessories information

- Accessories information

| Dia. | PSB500 | PSB830 | PSB930 | PSB1080 |

| 15 | KTB15-Q500 | KTB15-Q830 | KTB15-Q930 | KTB15-Q1080 |

| 20 | KTB20-Q500 | KTB20-Q830 | KTB20-Q930 | KTB20-Q1080 |

| 25 | KTB25-Q500 | KTB25-Q830 | KTB25-Q930 | KTB25-Q1080 |

| 32 | KTB32-Q500 | KTB32-Q830 | KTB32-Q930 | KTB32-Q1080 |

| 36 | KTB36-Q500 | KTB36-Q830 | KTB36-Q930 | KTB36-Q1080 |

| 40 | KTB40-Q500 | KTB40-Q830 | KTB40-Q930 | KTB40-Q1080 |

| 50 | KTB50-Q500 | KTB50-Q830 | KTB50-Q930 | KTB50-Q1080 |

Hot-dip Galvanized Coating Requirements

| Product Specification | Local Coating Thickness (um) | Mean Coating Thickness (um) | Max. Coating Thickness (um) |

| Threaded bar | 70~200 | 85 | 200 |

Corrugated Pipe

| Specification | Inner Dia. (mm) | Outer Dia. (mm) | Thickness (mm) | Material |

| KPC50/60 | 50 | 60 | 1.2 | PE |

| KPC50/65 | 50 | 65 | 2 | PE |

| KPC50/68 | 50 | 68 | 1.2 | PE |

| KPC65/75 | 65 | 75 | 1.2 | PE |

| KPC67/75 | 67 | 75 | 1.2 | PE |

| KPC65/85 | 65 | 85 | 2 | PE |

| KPC80/100 | 80 | 100 | 1.2 | PE |

| KPC85/95 | 85 | 95 | 1.5 | PE |

| KPC100/110 | 100 | 110 | 1.2 | PE |

| KPC100/125 | 100 | 125 | 2 | PE |

End Cap

| Specification | Corrugated Pipe Size (mm) | Inner Dia. (mm) | Outer Dia. (mm) | Length (mm) | Material |

| KPC60/65-120 | 60 | 60 | 65 | 120 | ABS |

| KPC68/73-120 | 68 | 68 | 73 | 120 | ABS |

| KPC75/80-120 | 75 | 75 | 80 | 120 | ABS |

| KPC85/90-120 | 85 | 85 | 90 | 120 | ABS |

| KPC100/105-120 | 100 | 100 | 105 | 120 | ABS |

| KPC110/120-120 | 110 | 110 | 120 | 120 | ABS |

End Cap with Hole

| Specification | Corrugated Pipe Size (mm) | Inner Dia. (mm) | Outer Dia. (mm) | Length (mm) | Material |

| KPC60/65-90H | 60 | 60 | 65 | 90 | ABS |

| KPC68/73-90H | 68 | 68 | 73 | 90 | ABS |

| KPC75/80-90H | 75 | 75 | 80 | 90 | ABS |

| KPC85/90-90H | 85 | 85 | 90 | 90 | ABS |

| KPC100/105-90H | 100 | 100 | 105 | 90 | ABS |

| KPC110/120-90H | 110 | 110 | 120 | 90 | ABS |

Smooth Plastic Pipe

| Specification | Inner Dia. (mm) | Outer Dia. (mm) | Thickness (mm) | Material |

| KPS51/54 | 51 | 54 | 1.5 | PE |

| KPS57/60 | 57 | 60 | 1.5 | PE |

| KPS66/69 | 66 | 69 | 1.5 | PE |

| KPS82/85 | 82 | 85 | 1.5 | PE |

| KPS82/88 | 82 | 88 | 3 | PE |

| KPS92/95 | 92 | 95 | 1.5 | PE |

| KPS102/105 | 102 | 105 | 1.5 | PE |

Nut: When the threaded rod is applied in the support field, it is used to transfer the load of the plate to the anchorage section by tensioning and prestressing thread bar.

| Specification | Thread Bar Size (mm) | Across Flat (mm) | Height (mm) | Weight (kg) |

| KTB15 | 15 | 30 | 50 | 0.22 |

| KTB20 | 20 | 32 | 45 | 0.17 |

| KTB25 | 25 | 50 | 60 | 0.7 |

| KTB32 | 32 | 65 | 72 | 1.4 |

| KTB36 | 36 | 65 | 80 | 1.45 |

| KTB40 | 40 | 70 | 100 | 2.12 |

| KTB50 | 50 | 80 | 110 | 3.1 |

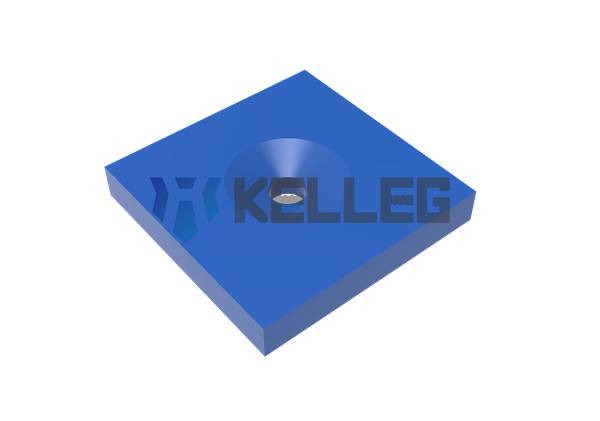

Plate: When the threaded rod is used in the support field, the component is in contact with the surrounding rock or soil and bears pressure from them.

| Specification | Thread Bar Size (mm) | Length (mm) | Thickness (mm) | Hole Dia. (mm) |

| KTB15 | 15 | 150 | 10 | 25 |

| KTB20 | 20 | 150 | 10 | 30 |

| KTB25 | 25 | 150 | 20 | 35 |

| KTB32 | 32 | 200 | 25 | 45 |

| KTB36 | 36 | 200 | 30 | 50 |

| KTB40 | 40 | 250 | 40 | 55 |

| KTB50 | 50 | 300 | 40 | 70 |

Coupler: It is mainly used to connect threaded rods to reach the service length.

| Specification | Thread Bar Size (mm) | Outer Dia. (mm) | Length (mm) | Weight (kg) |

| KTB15 | 15 | 38 | 110 | 0.8 |

| KTB20 | 20 | 38 | 110 | 0.7 |

| KTB25 | 25 | 50 | 132 | 1.35 |

| KTB32 | 32 | 60 | 168 | 2.4 |

| KTB36 | 36 | 70 | 200 | 3.6 |

| KTB40 | 40 | 75 | 220 | 5.2 |

| KTB50 | 50 | 90 | 270 | 9.8 |

Plastic Centralizer: It is an element that can locate the rebar centrally and ensure the grout thickness and has various types such as lantern centralizer, strap centralizer, and so on.

① Strap Centralizer:It can be divided into internal strap centralizer and external strap centralizer. It comes with a strap and becomes cylindrical when rolled up. It is used with steel bars and plastic pipes, which ensures uniform grouting thickness. It has low-temperature resistance and corrosion resistance. Compared with the lantern type, it can be installed from anywhere, convenient and fast.

| Internal Strap Centralizer | Specification | Thread Bar Size (mm) | Outer Dia. (mm) | Material |

| KCN25/45 | 25 | 45 | PE | |

| KCN25/50 | 25 | 50 | PE | |

| KCN25/60 | 25 | 60 | PE | |

| KCN25/65 | 25 | 65 | PE | |

| KCN25/75 | 25 | 75 | PE | |

| KCN28/45 | 28 | 45 | PE | |

| KCN28/50 | 28 | 50 | PE | |

| KCN28/75 | 28 | 75 | PE | |

| KCN32/45 | 32 | 45 | PE | |

| KCN32/50 | 32 | 50 | PE | |

| KCN32/65 | 32 | 65 | PE | |

| KCN32/75 | 32 | 75 | PE | |

| KCN32/85 | 32 | 85 | PE | |

| KCN40/75 | 40 | 75 | PE |

| External Strap Centralizer | Specification | Plastic Pipe Size (mm) | Outer Dia. (mm) | Material |

| KCW65/100 | 65 | 100 | PE | |

| KCW80/110 | 80 | 110 | PE | |

| KCW80/140 | 80 | 140 | PE | |

| KCW90/120 | 90 | 120 | PE | |

| KCW90/140 | 90 | 140 | PE |

② Lantern Centralizer:During installation, insert steel bar in lantern centralizer to ensure uniform grouting thickness and good corrosion resistance.

| Specification | Thread Bar Size (mm) | Outer Dia. (mm) | Material |

| KCD25/45 | 25 | 45 | UPVC |

| KCD25/55 | 25 | 55 | UPVC |

| KCD25/65 | 25 | 65 | UPVC |

| KCD25/75 | 25 | 75 | UPVC |

| KCD25/85 | 25 | 85 | UPVC |

| KCD25/95 | 25 | 95 | UPVC |

| KCD32/55 | 32 | 55 | UPVC |

| KCD32/65 | 32 | 65 | UPVC |

| KCD32/75 | 32 | 75 | UPVC |

| KCD32/85 | 32 | 85 | UPVC |

| KCD32/95 | 32 | 95 | UPVC |

| KCD40/55 | 40 | 55 | UPVC |

| KCD40/65 | 40 | 65 | UPVC |

| KCD40/75 | 40 | 75 | UPVC |

| KCD40/85 | 40 | 85 | UPVC |

| KCD40/115 | 40 | 115 | UPVC |

| KCD40/145 | 40 | 145 | UPVC |

| KCD50/80 | 50 | 80 | UPVC |

| KCD50/95 | 50 | 95 | UPVC |

| KCD50/145 | 50 | 145 | UPVC |

Nut: When the threaded rod is applied in the support field, it is used to transfer the load of the plate to the anchorage section by tensioning and prestressing thread bar.

| Specification | Thread Bar Size (mm) | Across Flat (mm) | Height (mm) | Weight (kg) |

| KTB15 | 15 | 30 | 50 | 0.22 |

| KTB20 | 20 | 32 | 45 | 0.17 |

| KTB25 | 25 | 50 | 60 | 0.7 |

| KTB32 | 32 | 65 | 72 | 1.4 |

| KTB36 | 36 | 65 | 80 | 1.45 |

| KTB40 | 40 | 70 | 100 | 2.12 |

| KTB50 | 50 | 80 | 110 | 3.1 |

Plate: When the threaded rod is used in the support field, the component is in contact with the surrounding rock or soil and bears pressure from them.

| Specification | Thread Bar Size (mm) | Length (mm) | Thickness (mm) | Hole Dia. (mm) |

| KTB15 | 15 | 150 | 10 | 25 |

| KTB20 | 20 | 150 | 10 | 30 |

| KTB25 | 25 | 150 | 20 | 35 |

| KTB32 | 32 | 200 | 25 | 45 |

| KTB36 | 36 | 200 | 30 | 50 |

| KTB40 | 40 | 250 | 40 | 55 |

| KTB50 | 50 | 300 | 40 | 70 |

Coupler: It is mainly used to connect threaded rods to reach the service length.

| Specification | Thread Bar Size (mm) | Outer Dia. (mm) | Length (mm) | Weight (kg) |

| KTB15 | 15 | 38 | 110 | 0.8 |

| KTB20 | 20 | 38 | 110 | 0.7 |

| KTB25 | 25 | 50 | 132 | 1.35 |

| KTB32 | 32 | 60 | 168 | 2.4 |

| KTB36 | 36 | 70 | 200 | 3.6 |

| KTB40 | 40 | 75 | 220 | 5.2 |

| KTB50 | 50 | 90 | 270 | 9.8 |

Plastic Centralizer: It is an element that can locate the rebar centrally and ensure the grout thickness and has various types such as lantern centralizer, strap centralizer, and so on.

① Strap Centralizer:It can be divided into internal strap centralizer and external strap centralizer. It comes with a strap and becomes cylindrical when rolled up. It is used with steel bars and plastic pipes, which ensures uniform grouting thickness. It has low-temperature resistance and corrosion resistance. Compared with the lantern type, it can be installed from anywhere, convenient and fast.

| Internal Strap Centralizer | Specification | Thread Bar Size (mm) | Outer Dia. (mm) | Material |

| KCN25/45 | 25 | 45 | PE | |

| KCN25/50 | 25 | 50 | PE | |

| KCN25/60 | 25 | 60 | PE | |

| KCN25/65 | 25 | 65 | PE | |

| KCN25/75 | 25 | 75 | PE | |

| KCN28/45 | 28 | 45 | PE | |

| KCN28/50 | 28 | 50 | PE | |

| KCN28/75 | 28 | 75 | PE | |

| KCN32/45 | 32 | 45 | PE | |

| KCN32/50 | 32 | 50 | PE | |

| KCN32/65 | 32 | 65 | PE | |

| KCN32/75 | 32 | 75 | PE | |

| KCN32/85 | 32 | 85 | PE | |

| KCN40/75 | 40 | 75 | PE |

| External Strap Centralizer | Specification | Plastic Pipe Size (mm) | Outer Dia. (mm) | Material |

| KCW65/100 | 65 | 100 | PE | |

| KCW80/110 | 80 | 110 | PE | |

| KCW80/140 | 80 | 140 | PE | |

| KCW90/120 | 90 | 120 | PE | |

| KCW90/140 | 90 | 140 | PE |

② Lantern Centralizer:During installation, insert steel bar in lantern centralizer to ensure uniform grouting thickness and good corrosion resistance.

| Specification | Thread Bar Size (mm) | Outer Dia. (mm) | Material |

| KCD25/45 | 25 | 45 | UPVC |

| KCD25/55 | 25 | 55 | UPVC |

| KCD25/65 | 25 | 65 | UPVC |

| KCD25/75 | 25 | 75 | UPVC |

| KCD25/85 | 25 | 85 | UPVC |

| KCD25/95 | 25 | 95 | UPVC |

| KCD32/55 | 32 | 55 | UPVC |

| KCD32/65 | 32 | 65 | UPVC |

| KCD32/75 | 32 | 75 | UPVC |

| KCD32/85 | 32 | 85 | UPVC |

| KCD32/95 | 32 | 95 | UPVC |

| KCD40/55 | 40 | 55 | UPVC |

| KCD40/65 | 40 | 65 | UPVC |

| KCD40/75 | 40 | 75 | UPVC |

| KCD40/85 | 40 | 85 | UPVC |

| KCD40/115 | 40 | 115 | UPVC |

| KCD40/145 | 40 | 145 | UPVC |

| KCD50/80 | 50 | 80 | UPVC |

| KCD50/95 | 50 | 95 | UPVC |

| KCD50/145 | 50 | 145 | UPVC |

More Than 50+ Companies Have Trusted Us For Quality

We are proud to provide high-quality rock drilling tool solutions that deliver reliable performance in demanding working conditions.

Rock Tools Applications

Trusted Rock Drilling Tools for Mining, Tunneling, Quarrying, and Hydropower Construction

Rock Tools in Mining

High-performance rock drilling tools for mining operations, designed to deliver fast penetration, long tool life, and lower drilling costs in hard-rock conditions.

Rock Tools in Tunneling

Reliable rock drilling tools for tunneling projects, ensuring precise excavation, safety, and efficiency across complex geological formations.

Rock Tools in Quarrying

Durable rock drilling tools for quarrying, helping you achieve clean blast holes, stable productivity, and reduced cost per meter drilled.

Rock Tools in Hydropower Project

Rock drilling tools engineered for hydropower construction, providing accurate and stable drilling for foundations, anchors, and structural support.

Quality Management Process

At Kelleg, quality control is built into every stage of production — from raw material sourcing to final inspection. Our rigorous Quality Management Process ensures stable performance, long service life, and reliable drilling results for every tool we deliver.

Supplier Management

We carefully evaluate and monitor our raw material suppliers to ensure stable quality from the very beginning of production.

Incoming Material Inspection

All incoming steel and carbide materials are strictly inspected for composition, hardness, and dimensional accuracy before entering production.

In-process Inspection

Key manufacturing steps are continuously monitored and measured to ensure every part meets design tolerances and performance standards.

Final Product Inspection

Each finished product undergoes comprehensive testing and inspection before shipment to guarantee consistent reliability on site.

Related Rock Drilling Tools

Explore our range of high-performance rock drilling tools, including DTH hammers, rock drill bits, and drill rods—engineered to maximize efficiency, durability, and productivity across mining, tunneling, quarrying, and hydropower projects.

Top Hammer Drilling Tools

High-performance top hammer drilling tools designed for surface and underground applications, delivering fast penetration and long service life in mining, quarrying, and construction projects.

DTH Drilling Tools

Durable DTH (Down-the-Hole) drilling tools engineered for deep and hard rock formations, ensuring maximum efficiency, reduced wear, and consistent performance in demanding drilling conditions.

Casing System

Reliable casing systems that provide stability and safety for boreholes, supporting smooth drilling operations while protecting equipment and maximizing productivity in various rock and soil conditions.

Request a Quote

Contact us now if you have any questions about our company and products. Any of your inquiry and suggestion will be highly appreciated. We will retain your information completely private.