Split Set

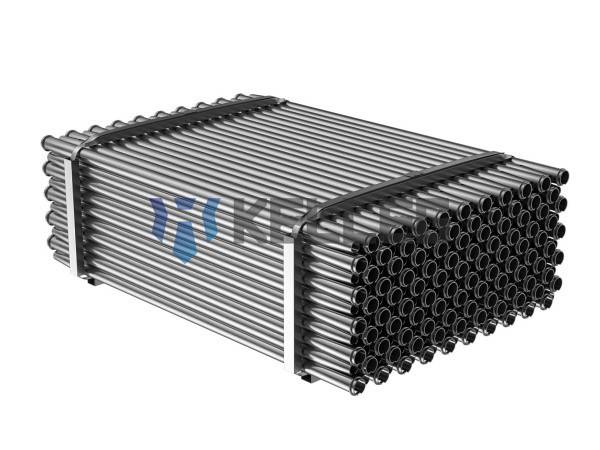

Split set is a new type anchor of full-length anchoring and active reinforcement of surrounding rock. It is composed of anchor rod and tray. The anchor rod is made of high-strength steel pipe and has longitudinal slits. When it is installed in a borehole slightly smaller than the pipe diameter, it can immediately apply radial pressure to the borehole through entire length and prevent the surrounding rock from sliding down. Coupled with the supporting force of tray, the surrounding rock is in a three-direction stress state to achieve rock stability.

- Application Fields: It is mainly used in mine engineering, which can quickly provide supporting force to achieve better supporting effects.

Advantage

- High-strength alloy strip steel is used as raw material. One end is forged with a tapered head for the anchor bar to insert the hole, and the other end is welded with an iron hoop to bear the weight of the plate.

- Installation is simple and can be completed only by impact.

- Anchorage agent is not required.

- The friction between the anchor bar and the rock mass is high.

- It has high shear and tensile strength.

- Equipped with a high-strength tray, the tray is evenly stressed.

- The drilling depth is greater than the anchor bar depth.

- It can provide timely support in radial and axial directions. It is unfit for permanent support in soft rock.

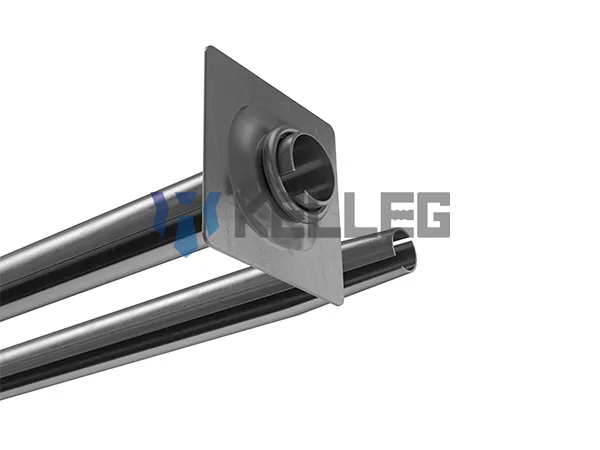

Split set is mainly composed of anchor rod and tray.

Anchor Rod: The circular pipe formed by the thin plate is rolled into a tubular shape and has a full-length longitudinal seam, which is used as a bolt in the support field. There are two wall thicknesses, 2.5mm and 3.0mm.

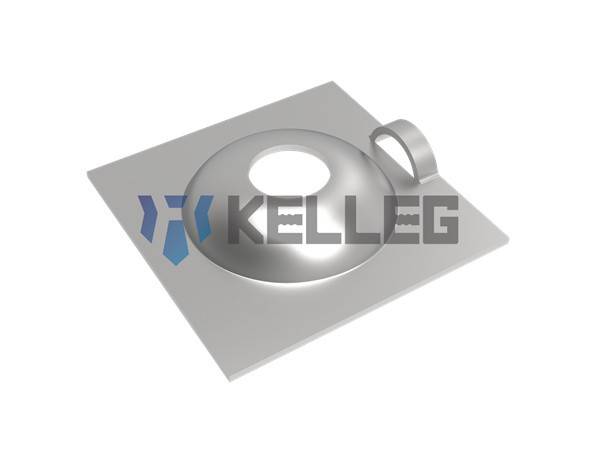

Tray: The shape is square, with a bowl-shaped protrusion in the middle, which is a component that transmits the tensile force of the bolt to the surrounding rock.

Common specifications: φ30, φ35, φ39, φ43, φ46.

Installation precautions

1. Determine the drill hole position according to design requirements, and then make the hole with a drill.

2. Use compressed air to blow away the rock dust in the hole.

3. Fit the anchor rod with plate, and drive the rod into the hole with percussion drill.

- Anchor Rod

- Tray

| Rod Dia. (mm) | Specification | Ultimate Tensile Load (KN) | Tensile Force of Ring (KN) | Cross Section Area (mm2) | Material | Recommended Drilling Hole Dia. (mm) |

|---|---|---|---|---|---|---|

| 33 | KFS33×2.5 | 100 | 75 | 214 | Q235 | 28~32 |

| KFS33×2.5 | 110 | 80 | 214 | Q355 | ||

| KFS33×3.0 | 110 | 80 | 253 | Q235 | ||

| KFS33×3.0 | 120 | 80 | 253 | Q355 | ||

| 39 | KFS39×2.5 | 110 | 80 | 251 | Q235 | 35~38 |

| KFS39×2.5 | 120 | 95 | 251 | Q355 | ||

| KFS39×3.0 | 120 | 95 | 297 | Q235 | ||

| KFS39×3.0 | 140 | 105 | 297 | Q355 | ||

| 43 | KFS43×2.5 | 115 | 90 | 283 | Q235 | 39~42 |

| KFS43×2.5 | 130 | 105 | 283 | Q355 | ||

| KFS43×3.0 | 130 | 105 | 335 | Q235 | ||

| KFS43×3.0 | 140 | 110 | 335 | Q355 | ||

| 46 | KFS46×2.5 | 120 | 100 | 299 | Q235 | 42~45 |

| KFS46×2.5 | 140 | 110 | 299 | Q355 | ||

| KFS46×3.0 | 140 | 110 | 354 | Q235 | ||

| KFS46×3.0 | 165 | 120 | 354 | Q355 |

| Rod Dia. (mm) | Specification | Length (mm) | Thickness (mm) | Bearing Capacity | Material | Weight (kg) |

|---|---|---|---|---|---|---|

| 33 | KFS33-150×150×4 | 150 | 4 | 70 | Q235 | 0.63 |

| KFS33-150×150×4 | 150 | 4 | 80 | Q355 | 0.63 | |

| 39 | KFS39-150×150×4 | 150 | 4 | 70 | Q235 | 0.62 |

| KFS39-150×150×4 | 150 | 4 | 80 | Q355 | 0.62 | |

| 43 | KFS43-150×150×6 | 150 | 6 | 80 | Q235 | 0.94 |

| KFS43-150×150×6 | 150 | 6 | 90 | Q355 | 0.94 | |

| 46 | KFS46-150×150×6 | 150 | 6 | 80 | Q235 | 0.94 |

| KFS46-150×150×6 | 150 | 6 | 90 | Q355 | 0.94 |

More Than 50+ Companies Have Trusted Us For Quality

We are proud to provide high-quality rock drilling tool solutions that deliver reliable performance in demanding working conditions.

Rock Tools Applications

Trusted Rock Drilling Tools for Mining, Tunneling, Quarrying, and Hydropower Construction

Rock Tools in Mining

High-performance rock drilling tools for mining operations, designed to deliver fast penetration, long tool life, and lower drilling costs in hard-rock conditions.

Rock Tools in Tunneling

Reliable rock drilling tools for tunneling projects, ensuring precise excavation, safety, and efficiency across complex geological formations.

Rock Tools in Quarrying

Durable rock drilling tools for quarrying, helping you achieve clean blast holes, stable productivity, and reduced cost per meter drilled.

Rock Tools in Hydropower Project

Rock drilling tools engineered for hydropower construction, providing accurate and stable drilling for foundations, anchors, and structural support.

Quality Management Process

At Kelleg, quality control is built into every stage of production — from raw material sourcing to final inspection. Our rigorous Quality Management Process ensures stable performance, long service life, and reliable drilling results for every tool we deliver.

Supplier Management

We carefully evaluate and monitor our raw material suppliers to ensure stable quality from the very beginning of production.

Incoming Material Inspection

All incoming steel and carbide materials are strictly inspected for composition, hardness, and dimensional accuracy before entering production.

In-process Inspection

Key manufacturing steps are continuously monitored and measured to ensure every part meets design tolerances and performance standards.

Final Product Inspection

Each finished product undergoes comprehensive testing and inspection before shipment to guarantee consistent reliability on site.

Related Rock Drilling Tools

Explore our range of high-performance rock drilling tools, including DTH hammers, rock drill bits, and drill rods—engineered to maximize efficiency, durability, and productivity across mining, tunneling, quarrying, and hydropower projects.

Top Hammer Drilling Tools

High-performance top hammer drilling tools designed for surface and underground applications, delivering fast penetration and long service life in mining, quarrying, and construction projects.

DTH Drilling Tools

Durable DTH (Down-the-Hole) drilling tools engineered for deep and hard rock formations, ensuring maximum efficiency, reduced wear, and consistent performance in demanding drilling conditions.

Casing System

Reliable casing systems that provide stability and safety for boreholes, supporting smooth drilling operations while protecting equipment and maximizing productivity in various rock and soil conditions.

Request a Quote

Contact us now if you have any questions about our company and products. Any of your inquiry and suggestion will be highly appreciated. We will retain your information completely private.