In industries such as mining, construction and geological exploration, shank adapters are critical components of rock drilling tools. When they fail, it can lead to equipment downtime, reduced productivity and safety hazards. Shank adapter breakage is not random; it usually occurs as a result of material issues, operational errors, and inadequate maintenance. This article explores the main reasons for shank adapter failure and provides practical strategies for optimising equipment performance.

The Pivotal Role of Shank Adapters

Shank adapters are the backbone of hydraulic rock drills. They handle impact piston loads and rotation motor torque, transferring energy to the bit for rock breaking. Breakage can cause disruption to operations, resulting in downtime, increased costs, and safety risks. Prioritising maintenance is therefore essential for smooth projects.

Main Reasons for Shank Adapter Failure

Shank adapter breakage often stems from multiple interacting factors. Based on industry insights and research, the top five causes are:

Material Fatigue and Stress Concentration

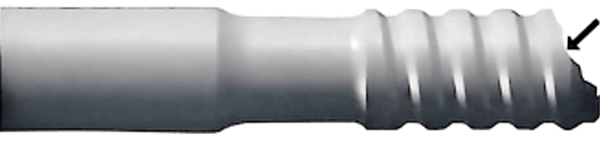

Shank adapters endure high-frequency impacts and torsional forces, facing thousands of alternating stresses per minute, including compressive, tensile, bending and shear stresses. When these stresses exceed the material’s fatigue limit, microcracks form at stress concentration points, such as thread roots or surface notches. These microcracks eventually lead to failure. Damage to related components, such as the shank sleeve or piston, can also indirectly result in breakage.

Fatigue failure at the threaded section is the most common type, for instance. Studies show that substandard manufacturing can increase the risk of breakage by two to three times compared to high-quality products.

Manufacturing and Heat Treatment Defects

The manufacturing process directly impacts the durability of the shank adapter. Improper heat treatment can introduce residual stresses or coarse-grain structures, leading to brittle fractures. Poor machining precision or high surface roughness in low-quality products can also promote crack initiation.

Industry data indicates that over 80% of shank adapter failures are linked to internal defects or uneven hardness resulting from improper heat treatment. It is therefore critical to choose products from reputable manufacturers.

A Hidden Risk in High-Frequency Impacts

Rock drills produce 40–110 impacts per second, so connections must be highly stable. Bolts, which secure key components, lose their preload under prolonged vibration, which causes them to loosen. This destabilises the drill structure, triggering irregular oscillations. As the energy transfer hub, the shank adapter faces excessive stress, which damages itself and components such as the impact piston and rotation motor, accelerating overall wear.

To prevent this, regularly inspect the tightness of the bolts using a torque wrench to ensure they meet the manufacturer’s standards. Choose high-quality bolts and pre-tighten them before heavy-duty tasks to minimise the risk of loosening.

Excessive Clearance Sparks Vibration Issues

Guide bushings ensure stable movement of the shank adapter for efficient energy transfer. Under normal conditions, there is a proper gap between the bushing and the adapter. However, friction from extended use causes bushing wear. If the inner bore wears beyond acceptable limits and isn’t replaced, the gap widens, causing the front end to wobble in a manner similar to a ‘whiplash’ effect and hastening fatigue damage. When the gap exceeds 1 mm, guidance weakens and the adapter enters an unstable ‘vibration mode’. This generates additional alternating stresses that form fatigue cracks at stress concentration points, leading to breakage.

Prevent this by routinely checking bushing clearance, replacing worn parts with durable materials and verifying the fit before operation. A clean work environment reduces wear caused by debris.

Heat Buildup Fuels Wear and Crack Risks

Proper lubrication is vital for the shank adapter and guide bushing. Inadequate lubrication increases friction, trapping heat, and causing temperatures to spike. High temperatures reduce the wear resistance of the bushing and alter the properties of the adapter material, making it more brittle and susceptible to cracking. Under continuous impact, these cracks can spread rapidly, causing failure.

To counter this, use the recommended lubricants and replenish them on schedule. Temperature monitoring systems can detect anomalies early. Using heat-resistant materials also enhances durability.

Additional Factors

Improper Propulsion Pressure

Excessive pressure or torque can cause breakage. Propulsion pressure affects stress wave transmission and adapter loading. If it is too low or if there are empty strikes, waves accumulate internally, causing fatigue failure. If the pressure is too high or if the rotation speeds are mismatched, the adapter faces loads beyond its design limits, especially during hard rock drilling. Eager to make progress, operators may neglect chip removal, which can cause tool jamming. Overpressure can bend the adapter, and when combined with impact stresses, this can accelerate failure.

Optimise by adjusting the pressure based on the hardness of the rock and the drill specifications, and avoid empty strikes. Use pressure sensors for real-time monitoring and provide operators with training on the correct settings.

Uneven Loading from Installation Errors

Proper installation of the feed beam is essential. Common issues include deviations in the drilling angle or unstable setups. Misalignment between the adapter and drill arm introduces radial forces that bend the adapter. This uneven loading can cause stress concentration under high-frequency impacts, leading to breakage.

Prevent this by using precision tools to ensure alignment during setup and by calibrating regularly. Using professional installation teams can reduce human error.

Corrosive liquids

In corrosive environments, acidic or corrosive substances can erode the adapter’s surface, creating grooves. These act as stress concentration points, initiating fatigue cracks and leading to failure.

In such conditions, apply protective coatings or clean the adapter regularly. Vibration sensors can help to detect anomalies early on.

How to prevent shank adapter breakage

Prevention is better than repair. These steps can significantly reduce the risk of breakage:

- Regular inspections and maintenance: Check bushing wear and clearance per shift and replace parts that exceed the standard. Ensure tool alignment and secure installation.

- Optimise operating parameters: Adjust the impact force and rotation speed according to the hardness of the rock, to avoid overloading. Clear chips promptly to prevent jamming.

- Choose high-quality materials: Select rigorously heat-treated adapters from trusted brands KELLEG to ensure accessory compatibility and avoid mixing brands.

- Environmental Control: Use protective coatings or clean surfaces in corrosive settings. Monitor vibrations to identify issues early.

- Training and monitoring: Train operators thoroughly and use tools such as vibration sensors to track stress changes in real time.

Implementing these measures can extend equipment life by 20%-50% and significantly boost productivity.

Conclusion

Breakage of shank adapters is often the result of operational errors and maintenance oversights. Focus on proper setup, regular maintenance, pressure control, and lubrication to extend adapter life, improve safety, and enhance efficiency. For persistent issues, consult KELLEG’s professional technical support to optimise your drilling process.