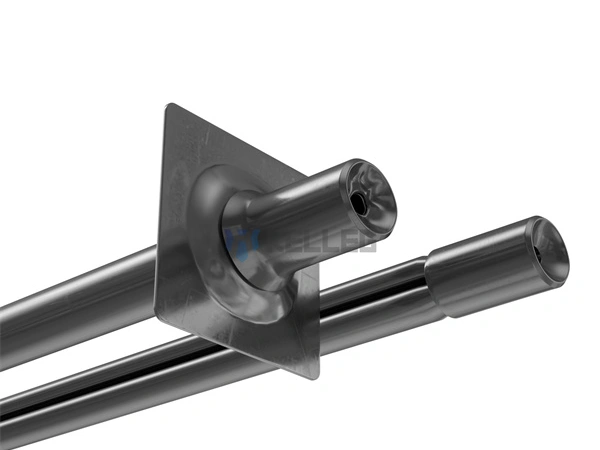

Expandable Rock Bolt

The expandable rock bolt is made out of a thin-walled steel tube folded on itself. The expandable rock bolt is secured by injecting high-pressure water into the hollow cavity of the bar once it is inserted into the borehole. This process instantly strengthens and supports the structure by creating friction between the bolt and the borehole wall. It is composed of end sleeves, retaining rings, liquid injection ends and plates.

- Function: hanging, beam forming, slope stabilization, arch forming, internal pressure

- Application scenarios: hard rock mines, tunnels or emergency rescue

Our Features

- Quality: We focus on material selection and quality control to ensure our products are of superior quality.

- Fast: Our unique design and precision manufacturing processes enable fast and reliable expansion and anchoring, ensuring optimal performance and a dependable connection.

- Cost-effective: It has high anchoring force, stability, corrosion resistance, and longer service life.

Features

- Simple, safe and immediate rock support

- Easy and fast installation

- Full length immediate anchorage

- No harmful bonding agents (resin / cement)

- High performance in hard, fractured and soft rock

Working Principle

Install the anchor rod in the drill hole and inject high-pressure water. After the water pressure exceeds the elastic limit of the pipe material, the rod will undergo permanent plastic expansion deformation with the geometry of the drill hole, making it firmly embedded in the surrounding rock. In addition, when the rod expands, the anchor rod exerts a higher pressure on the surrounding rock mass, forcing the surrounding rock to generate strain, increasing the surrounding rock stress, and in turn, the surrounding rock also produces corresponding extrusion on the anchor rod. During the expansion, because its diameter become larger, there is a certain amount of shrinkage along the longitudinal direction, which causes the anchor plate to be pressed tightly against the surface of the surrounding rock, generating upward supporting force, thereby applying prestress to the surrounding rock.

Construction procedure

- Drill the hole

- Insert the rock bolt

- Start the water pump to expand the rock bolt

- Installation completed

- Expandable Rock Bolt

| Item | Unit | Premium Line | Manganese Line | ||||

| Pm 12 | Pm 16 | Pm 24 | Mn 12 | Mn 16 | Pm 24 | ||

| Material | – | Q355 | Q355 | ||||

| Failure Load≥ | kN | 120 | 160 | 240 | 120 | 140 | 200 |

| Yield Load≥ | kN | 100 | 130 | 200 | 90 | 140 | 180 |

| Elongation≥ | % | 10 | 10 | 10 | 20 | 20 | 20 |

| Grouting Pressure | Bar | 300 | 240 | 300 | 300 | 240 | 300 |

| Section Diameter | mm | 28 | 36 | 36 | 27.5 | 36 | 36 |

| Round Tube Diameter | mm | 41 | 54 | 54 | 41 | 54 | 54 |

| Wall Thickness | mm | 2 | 2 | 3 | 2 | 2 | 3 |

| Upper Casing Diameter | mm | 28 | 38 | 38 | 28 | 38 | 38 |

| Expansion casing diameter | mm | 30/36 | 41/48 | 41/48 | 30/36 | 41/48 | 41/48 |

| Best Hole Enlargement | mm | 35-38 | 45-51 | 45-51 | 35-38 | 45-51 | 45-51 |

| Hole Diameter Range | mm | 32-39 | 43-52 | 43-52 | 32-39 | 43-52 | 43-52 |

More Than 50+ Companies Have Trusted Us For Quality

We are proud to provide high-quality rock drilling tool solutions that deliver reliable performance in demanding working conditions.

Rock Tools Applications

Trusted Rock Drilling Tools for Mining, Tunneling, Quarrying, and Hydropower Construction

Rock Tools in Mining

High-performance rock drilling tools for mining operations, designed to deliver fast penetration, long tool life, and lower drilling costs in hard-rock conditions.

Rock Tools in Tunneling

Reliable rock drilling tools for tunneling projects, ensuring precise excavation, safety, and efficiency across complex geological formations.

Rock Tools in Quarrying

Durable rock drilling tools for quarrying, helping you achieve clean blast holes, stable productivity, and reduced cost per meter drilled.

Rock Tools in Hydropower Project

Rock drilling tools engineered for hydropower construction, providing accurate and stable drilling for foundations, anchors, and structural support.

Quality Management Process

At Kelleg, quality control is built into every stage of production — from raw material sourcing to final inspection. Our rigorous Quality Management Process ensures stable performance, long service life, and reliable drilling results for every tool we deliver.

Supplier Management

We carefully evaluate and monitor our raw material suppliers to ensure stable quality from the very beginning of production.

Incoming Material Inspection

All incoming steel and carbide materials are strictly inspected for composition, hardness, and dimensional accuracy before entering production.

In-process Inspection

Key manufacturing steps are continuously monitored and measured to ensure every part meets design tolerances and performance standards.

Final Product Inspection

Each finished product undergoes comprehensive testing and inspection before shipment to guarantee consistent reliability on site.

Related Rock Drilling Tools

Explore our range of high-performance rock drilling tools, including DTH hammers, rock drill bits, and drill rods—engineered to maximize efficiency, durability, and productivity across mining, tunneling, quarrying, and hydropower projects.

Top Hammer Drilling Tools

High-performance top hammer drilling tools designed for surface and underground applications, delivering fast penetration and long service life in mining, quarrying, and construction projects.

DTH Drilling Tools

Durable DTH (Down-the-Hole) drilling tools engineered for deep and hard rock formations, ensuring maximum efficiency, reduced wear, and consistent performance in demanding drilling conditions.

Casing System

Reliable casing systems that provide stability and safety for boreholes, supporting smooth drilling operations while protecting equipment and maximizing productivity in various rock and soil conditions.

Request a Quote

Contact us now if you have any questions about our company and products. Any of your inquiry and suggestion will be highly appreciated. We will retain your information completely private.