Wire Mesh

The main product of wire mesh is steel bar welded mesh. Steel bar welded mesh is a product that the steel bars are arranged in vertical and horizontal directions respectively with a certain distance and the intersection points are welded. It is widely used in various construction scenarios such as building construction, slope support, tunnel support, mining engineering, bridge construction and subgrade mesh reinforcement.

Advantages

- High dimensional accuracy

Automatic intelligent production equipment is adopted for processing, thus the grid spacing and the number of steel bars are accurate and evenly arranged.

- Good overall performance

It has the characteristics of large stiffness, good elasticity, high solder joint strength and good shear resistance.

- Improve project quality

The vertical and horizontal steel bars are welded into a network structure so that the product can be evenly stressed, not only effectively reduce the probability of concrete cracks, but also improve project quality.

- Reduce project budget

Mechanized production can shorten working hours by more than 50%, greatly shorten the construction period and reduce comprehensive cost.

- Wide application range, safe and reliable

In tunnel, coal mine and other limited construction space can also be constructed safely.

- Anti-corrosion process can be added

Anti-corrosion treatment such as galvanizing and dipping can be added to improve anti-corrosion performance and service life of the product.

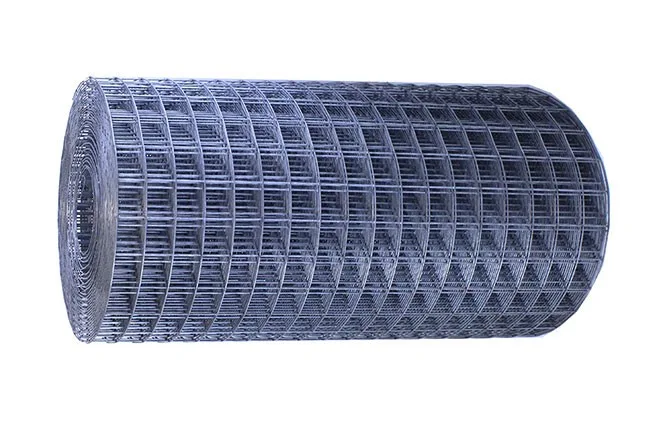

Welded Wire Mesh

Galvanized welded mesh is made with plain steel wire welded together in square opening, then going through the hot dipped zinc coating process. Designed for construction, building reinforcement and fences, it enjoys the feature of corrosion resistance compared with plain black iron welded mesh. Galvanized welded mesh can be fabricated into constructional reinforcement panels and wire mesh partitions.

Materials: High quality low carbon steel wire, stainless steel wire

Surface treatment

hot-dipped galvanized, electro galvanized, PVC coated, painted, untreated.

Features

strong welded points and bright luster. The mesh doesn’t come loose even if cut in parts or being exerted force on parts. Compared with general iron wire, the products are better in respects of anti-corrosive and anti-rust.

Application

They are widely used in industry, agriculture, construction, transport and mining. Such as machine protection cover, ranch fender, garden fence, window protection fender, passage fender, etc.

Welded Wire Mesh Panels

Welded wire mesh panels with smooth surface and firm structure are made of high quality low carbon steel, stainless steel and aluminum alloy steel. The common size of panel usually is 1800 mm × 3000 mm, we also accept other sizes for customers’ needs.

Types: Stainless steel mesh, black wire mesh, galvanized wire mesh, plastic coated mesh, framed mesh.

Surface treatment

PVC coated, PVC praying, hot-dipped galvanized and electric galvanized.

The PVC coated and galvanized surfaces have good corrosion resistance and weather resistance, so it can provide a long service life.

PVC coated and sprayed welded wire mesh panels has corrosion resistance, aging resistance, sunshine resistance and weather resistance.

Colors available for PVC coated welded wire mesh: Green, blue, white or other colors at customers‘ request.

Application

Welded wire mesh is characteristic of its fine qualities, sturdiness and durable, economy as well as attractiveness. It is widely used in industry, farming, construction, transportation and mining for protection of structure.

Feature: smooth surface, firm structure, corrosion resistance, aging resistant, weather resistant, long service life, product parameters.

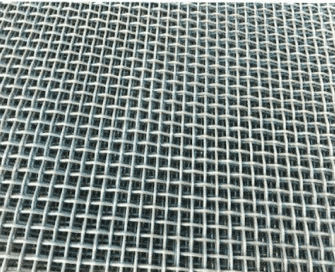

Woven Mesh

Woven mesh is usually made of black steel wire, white steel wire, lead wire, stainless steel wire, etc. It is crimped before woven, with stable structure.

Application

Woven mesh is mainly used in coal, mine, building, etc.

What is the construction process of welded steel mesh?

Play the steel bar position line on the formwork → lay the lower mesh sheet → reserve and embed civil engineering and hydropower → install the upper layer mesh sheet to build a berm → acceptance of concealed works → review and maintain when pouring concrete.

According to the type of steel bar, how to classify the welded steel mesh?

Cold-rolled ribbed steel bar welded mesh, hot-rolled ribbed steel bar welded mesh, cold-rolled smooth steel bar welded mesh

- Welded Wire Mesh

- Welded Wire Mesh Panels

- Woven Mesh

| Grid Spacing (mm) | Material | Rebar Dia. (mm) | Surface Treatment | |

| 100*100 |

hard-drawn wire/ |

Q235/Q195 |

5/6/7/8/9/10/ |

original color of rebar/ |

| 100*150 | ||||

| 100*200 | ||||

| 150*150 | ||||

| 150*200 | ||||

| 200*200 | ||||

| Opening inth | Opening mm | Wire Diameter BWG | Wire Diameter mm |

| 1″x1″ | 25mmx25mm | 14#-11# | 2.0mm-3mm |

| 2″x1″ | 50mmx25mm | 14#-8# | 2.0mm-4mm |

| 2″x2″ | 50mmx50mm | 14#-8# | 2.0mm-4mm |

| 3″x2″ | 75mmx50mm | 14#-6# | 2.0mm-5mm |

| 3″x3″ | 75mmx75mm | 14#-6# | 2.0mm-5mm |

| 4″x2″ | 100mmx50mm | 14#-4# | 2.0mm-6mm |

| 4″x4″ | 100mmx100mm | 14#-4# | 2.0mm-6mm |

| 5″x5″ | 125mmx125mm | 14#-4# | 2.0mm-6mm |

| 6″x6″ | 150mmx150mm | 14#-4# | 2.0mm-6mm |

| Wire Gauge SWG | Wire Diameter mm | Mesh inch | Aperture mm | Weight Kg/m |

| 14 | 2 | 21 | 1 | 4.2 |

| 8 | 4.05 | 18 | 1 | 15 |

| 25 | 0.5 | 20 | 0.61 | 2.6 |

| 23 | 0.61 | 18 | 0.8 | 3.4 |

| 24 | 0.55 | 16 | 0.1 | 2.5 |

| 24 | 0.55 | 14 | 0.12 | 4 |

| 22 | 0.71 | 12 | 0.14 | 2.94 |

| 19 | 1 | 2.3 | 0.18 | 1.45 |

| 6 | 4.8 | 1.2 | 2 | 20 |

| 6 | 4.8 | 1 | 2 | 20 |

| 6 | 4.8 | 0.7 | 3 | 14 |

| 14 | 2 | 5.08 | 0.3 | 12 |

| 14 | 2 | 2.1 | 1 | 2.5 |

| 14 | 2 | 3.6 | 1.5 | 1.9 |

| Wire Gauge SWG | Wire Diameter mm | Mesh inch | Aperture mm | Weight Kg/m |

| 14 | 2 | 21 | 1 | 4.2 |

| 8 | 4.05 | 18 | 1 | 15 |

| 25 | 0.5 | 20 | 0.61 | 2.6 |

| 23 | 0.61 | 18 | 0.8 | 3.4 |

| 24 | 0.55 | 16 | 0.1 | 2.5 |

| 24 | 0.55 | 14 | 0.12 | 4 |

| 22 | 0.71 | 12 | 0.14 | 2.94 |

| 19 | 1 | 2.3 | 0.18 | 1.45 |

| 6 | 4.8 | 1.2 | 2 | 20 |

| 6 | 4.8 | 1 | 2 | 20 |

| 6 | 4.8 | 0.7 | 3 | 14 |

| 14 | 2 | 5.08 | 0.3 | 12 |

| 14 | 2 | 2.1 | 1 | 2.5 |

| 14 | 2 | 3.6 | 1.5 | 1.9 |

More Than 50+ Companies Have Trusted Us For Quality

We are proud to provide high-quality rock drilling tool solutions that deliver reliable performance in demanding working conditions.

Rock Tools Applications

Trusted Rock Drilling Tools for Mining, Tunneling, Quarrying, and Hydropower Construction

Rock Tools in Mining

High-performance rock drilling tools for mining operations, designed to deliver fast penetration, long tool life, and lower drilling costs in hard-rock conditions.

Rock Tools in Tunneling

Reliable rock drilling tools for tunneling projects, ensuring precise excavation, safety, and efficiency across complex geological formations.

Rock Tools in Quarrying

Durable rock drilling tools for quarrying, helping you achieve clean blast holes, stable productivity, and reduced cost per meter drilled.

Rock Tools in Hydropower Project

Rock drilling tools engineered for hydropower construction, providing accurate and stable drilling for foundations, anchors, and structural support.

Quality Management Process

At Kelleg, quality control is built into every stage of production — from raw material sourcing to final inspection. Our rigorous Quality Management Process ensures stable performance, long service life, and reliable drilling results for every tool we deliver.

Supplier Management

We carefully evaluate and monitor our raw material suppliers to ensure stable quality from the very beginning of production.

Incoming Material Inspection

All incoming steel and carbide materials are strictly inspected for composition, hardness, and dimensional accuracy before entering production.

In-process Inspection

Key manufacturing steps are continuously monitored and measured to ensure every part meets design tolerances and performance standards.

Final Product Inspection

Each finished product undergoes comprehensive testing and inspection before shipment to guarantee consistent reliability on site.

Related Rock Drilling Tools

Explore our range of high-performance rock drilling tools, including DTH hammers, rock drill bits, and drill rods—engineered to maximize efficiency, durability, and productivity across mining, tunneling, quarrying, and hydropower projects.

Top Hammer Drilling Tools

High-performance top hammer drilling tools designed for surface and underground applications, delivering fast penetration and long service life in mining, quarrying, and construction projects.

DTH Drilling Tools

Durable DTH (Down-the-Hole) drilling tools engineered for deep and hard rock formations, ensuring maximum efficiency, reduced wear, and consistent performance in demanding drilling conditions.

Casing System

Reliable casing systems that provide stability and safety for boreholes, supporting smooth drilling operations while protecting equipment and maximizing productivity in various rock and soil conditions.

Request a Quote

Contact us now if you have any questions about our company and products. Any of your inquiry and suggestion will be highly appreciated. We will retain your information completely private.